I had to agree that it was an unusual gas station.

It looked like an airport control tower with a cantilevered roof that protected the customers at the gas pumps – protection from rain and sun that is common today but in 1978, and certainly 20 years earlier when built, it was novel. The pumps were fueling the local cars: a mix of old gas guzzlers and newer more fuel-efficient models that were a response to the oil embargos of the 70s.

We were on the way to our business destination—the US Steel mine near Mountain Iron Minnesota, a town slowly being eaten up by the open pit mine as it followed the deposits of diffuse iron known as taconite.

I was the passenger in Steve Haverberg’s VW microbus. Steve was familiar with the area and knew I would enjoy seeing a gas station that had been designed by Frank Lloyd Wright. We needed gas anyway and it was a good time to stop and stretch.

Another vehicle was also on its way to the mine, but had taken a more direct route. It was equipped with a 4-foot long cylindrical probe, to be lowered by cable into a drill hole. A custom-built instrument specialized for detecting iron ore was also in that truck.

Steve Haverberg and I worked for Bison Instruments, a company of only 20 people that made specialized equipment for a small market of geophysical engineers. Steve was Bison’s salesperson, the driving force behind this project, and he had convinced someone at US Steel that we could provide a solution to their problem of getting accurate measurements of the underlying rock formations of the mine.

The concept for this instrument was that a coil inside the probe, a simple copper wire of a few hundred turns, would be used to sense the magnetic properties of the rock that surrounded it. With applied current, it became an electromagnet, attracting anything containing iron. That magnetic attraction can be sensed by electronic circuits, measured, and displayed. The instrument that does this is called a magnetic susceptibility meter, but I will just call it a magnetometer.

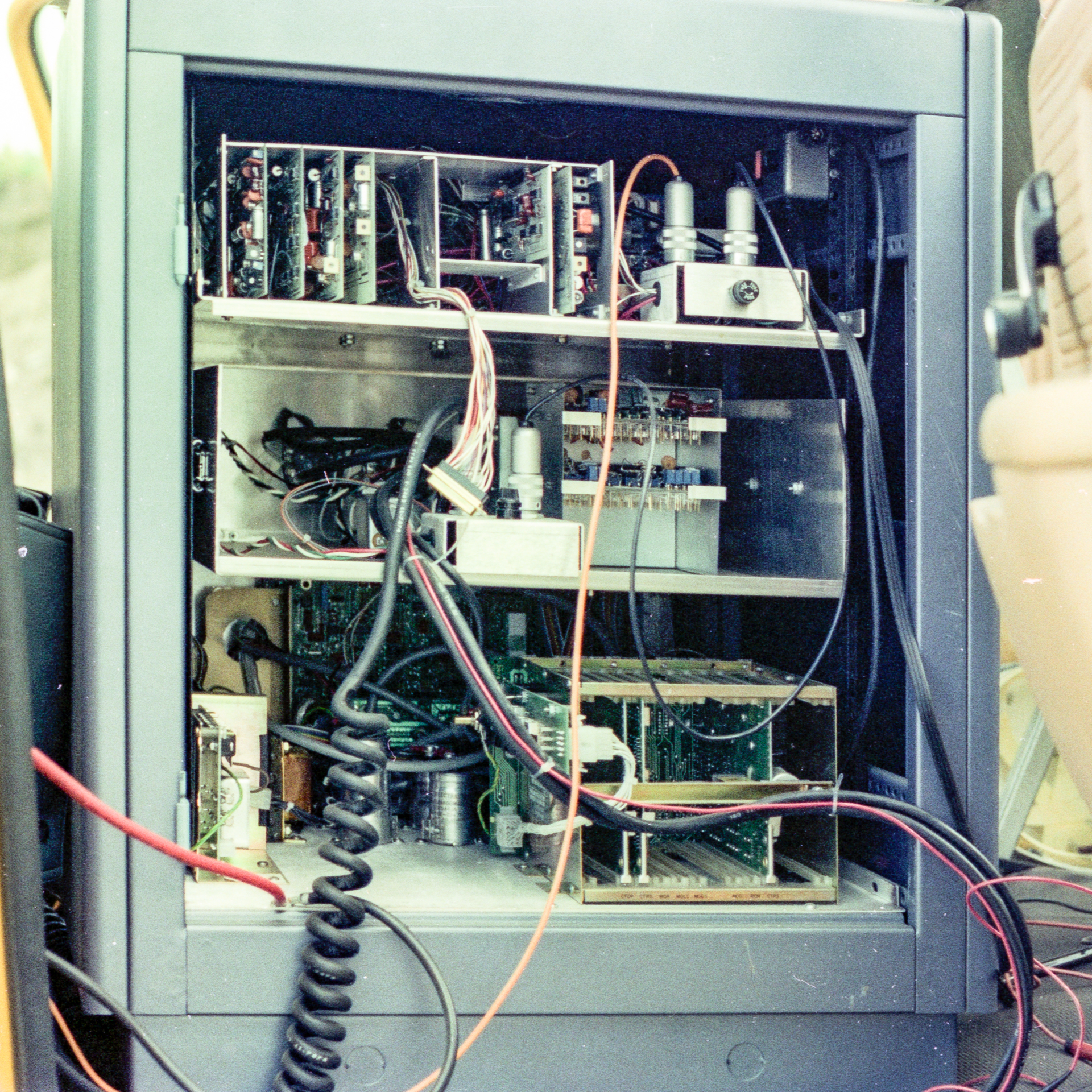

My part in this project was initially rather minor: modify an existing instrument so that it could take multiple measurements, and save and display them as a sequence. Today, this is a simple thing to do, but in 1978 it consumed weeks of design effort and circuit modifications (cuts and jumpers). Although the result might be described as a hack of butchered components, I was proud that I could figure it out and that it worked!

I was surprised when my Frankenstein instrument was installed. Unlike the other instruments that Bison made, which resided in ruggedized portable cases that could be backpacked to a remote site, my circuit boards, displays, and chassis got installed into a truck! It showed up one day, equipped with a motorized spool that fed a cable to an overhead boom that guided a probe down a drill hole. I had never seen something this sophisticated from our company. The probe contained the electrical coil that connected to my circuits. The cable from the spool triggered a switch every half-foot or so, which told the instrument to take the next measurement. Amazingly, when we connected it all up, it worked! At least it worked in the garage behind our shop.

A few days later, I learned that I would be traveling to Minnesota’s “iron range” to deliver the system to our customer. US Steel operated MinnTac, one of the largest taconite mines in the world. I would be there with Steve, and with Clark Johnson, a physicist familiar with Bison’s magnetometer and consulting on this project. The original Bison instrument measured small one-inch core samples placed inside a sensing coil. This instrument would be measuring a one-foot coil inserted into an even larger diameter hole in the ground. Clark was responsible for the electronics that could deliver magnetic susceptibility values from this new configuration.

We would be delivering the system, testing it, and showing the mining engineers at US Steel how to use it. Which brings us back to our stop at the Frank Lloyd Wright gas station.

As a young engineer, this was my first time on a business trip– at a customer site for several days with work associates. It was exciting! I tagged along with the more experienced members of our group which now included a mining engineer, Jack Eloranta, our contact person at US Steel. Jack was sharp, a quick study. It didn’t take much explanation for him to understand the workings of our system, and he could explain to us the workings of this immense mining operation. I thought he was a pretty cool guy, which made me wonder why he was working in this remote part of our state in the scarred terrain of an open pit iron mine outside a shriveling town whose heyday had been decades earlier. His answer was simple: “When you are trained as a mining engineer, you work where the mines are.”

After donning helmets, safety shoes and glasses, he guided us out into the vast mine, along routes created for the giant ore-hauling trucks to bring the blasted rock debris to the mills, where it would be crushed and concentrated. As we followed one of the behemoths, Jack explained that they were electrically powered, and each wheel had a sensor to detect when the motors were overheating due to the immense load. He said that the truck drivers don’t aim for a maximum speed to get their ore delivered; they run at the maximum temperature that the motors allow, whatever speed results!

We were headed for a series of drill holes where we would be testing our probe. The holes were either exploratory, for obtaining core samples using specialized diamond drill heads, or they were drilled for the eventual purpose of being filled with explosives for blasting. In either case, they existed at locations in the open pit mine where they wanted to know the magnetite concentration as a function of depth, so they could make the costly decisions about where to dig for economically profitable ore.

Eventually we arrived at the first test hole to measure. The truck maneuvered into position and lowered its probe. We were quite excited to see the readings move from zero while the probe was suspended above the surface, to a positive magnetometer reading as it entered the hole.

I wondered if the measurements were accurate, but this was Clark’s domain. The coil sensor was measuring magnetic susceptibility, an abstract physical quantity that characterized the magnetic fields that were affected by the presence of magnetite. The mining operation wanted to know the concentration of magnetite in the rock, to decide if it was worth blasting and processing. And this was Jack’s domain. Some sort of calibration would be needed.

But that wasn’t today’s purpose. We just needed a proof of operation that the magnetic susceptibility profile of the hole could be obtained by our instrumentation. And so far it looked good.

But as the probe dropped further, we encountered a disruption of the signal. The amplitude, which had been gradually moving up and down as the probe passed by strata of high and low concentration ore, suddenly started jumping around. It was like a seismograph was suddenly hit by an earthquake, and the previously quiescent wave was disrupted by wild oscillations. It continued with further depth, and so we pulled the probe back up. It gradually recovered as we approached the surface and by the time it was out, it seemed like the system was behaving normally again.

This was a pretty big blow. We didn’t really understand what had just happened or what to do next, but there was another drill hole that was on our test schedule. We decided to continue on and measure it, but, like the first hole, this one started out fine, but then went crazy with the seismic shock-like signal. It occurred at a slightly different depth, but was qualitatively the same result.

This left us in a really bad position. The expensive instrument and rig was not providing the measurements that were expected by our customer. We departed the mine with Steve, the project manager, and me, the rookie engineer, being discouraged. Clark, the physicist, was merely puzzled.

As we settled into our accommodations in the nearby mining town of Hibbing, Steve employed the problem-solving methods of salespeople everywhere by ordering a case of beer. I was examining my schematics to see if there was some circuit condition that would overflow or otherwise trigger the measurement behavior we had seen.

Clark was thinking. And by thinking, I mean talking. He had a sharp mind, but while processing the physics in his head, there was a verbal flow on tap of his thought process. I understood some of it—I had a few semesters of electromagnetic field theory in my training and could make weak responses to Clark’s external mental dialog. Steve followed along and understood enough to suggest our next action.

It was Clark’s conjecture that the drill holes contained water at some depth, probably related to the water table and rain history since it had been drilled. When the probe coil encountered the water, it would completely transform, effectively “shorting out” its magnetic field, preventing it from penetrating the external rock, instead measuring the properties of the water.

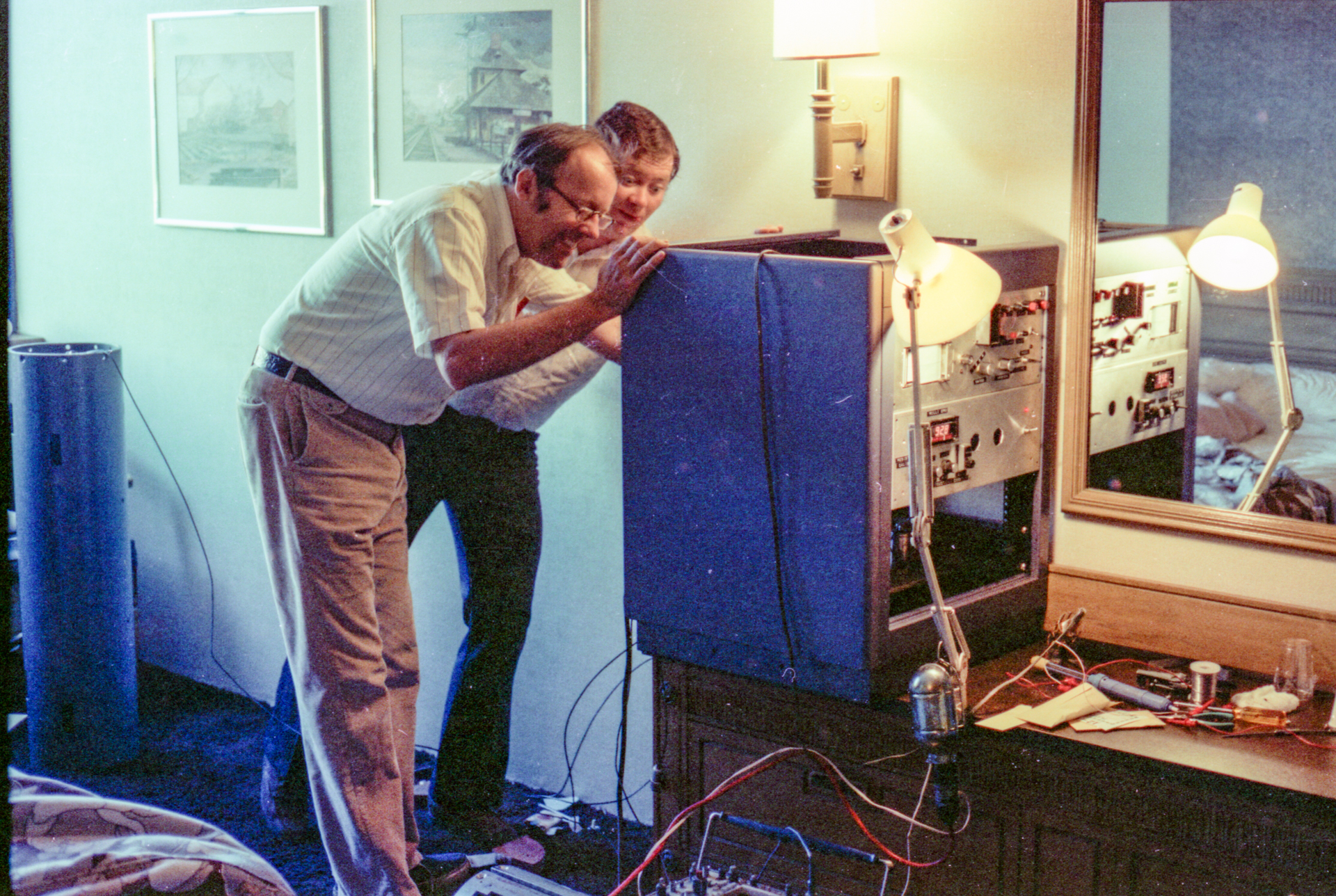

It was Steve who thought we could test this theory that very evening right there in the hotel room. With beer in hand, he piloted the truck to near the window of our (first floor) room. A truck designed to navigate the makeshift roads of an open pit mine had no trouble climbing the curb and crossing the lawn and gardens of a hotel. We fed the probe through the window, letting out enough cable that it could cross the room, enter the bathroom, and come to rest in the bathtub. The instrument chassis was maneuvered into the room as well, and we now had a way of simulating the probe being immersed in water!

We fired up the instrument and were pleased to find it sensing the iron content of the bathtub. We then started filling the tub and watched the readout. As the water rose high enough to enter the probe, the measurements started becoming erratic. The transition to chaos was different from what we had observed in the field, but we were not plunging the probe into a water-filled hole; we were watching an incoming tide gradually overwhelm the sensing coil. Eventually, the measurements were the same!

Our bathtub test had demonstrated the cause of the failure, and pointed the way to a solution.

We did not return to the mine on that trip. Instead, we headed home to figure out the next design iteration for our coil. The first one had been made with hundreds of turns of wire wrapped around a form, which had then been removed so that the coil was open to the air (and water). The next coil was also made using a form, but this time we left it in place and sealed the whole assembly, making it impossible for water to find its way through the center of the coil. This was enough to keep it from “shorting out” when immersed in water.

The improved probe design was later proven to work, and US Steel took delivery of our system, earning a nice bonus for Steve and enhancing both of our statuses professionally. The rig would prove to pay for itself many times over during its operation at MinnTac.

Steve Haverberg would eventually leave Bison Instruments and go on to become the vice president of a company that makes water well and drilling equipment. But first he would introduce me to more adventures including (while attending a technical conference in New Orleans), visiting oyster bars and other unique attractions along infamous Canal Street.

Jack Eloranta went on to earn a Master’s degree in mining engineering based on his experience and work with downhole magnetic susceptibility instruments. He later founded his own mining engineering consulting business.

I continued to work at Bison for several more years, designing seismographs and other instruments for geophysical engineering. It was an exciting time, as microprocessors had just become available and were being incorporated to make ever smarter and more capable instruments.

Clark Johnson continues, to this day, making fascinating inventions by applying his deep intuitions and understanding of physics. Our paths would cross again a few years later at a startup company he founded based on newly discovered properties of a magnetic material: cobalt-chrome. I was hired to design the electronics for a high-density disk drive based on that technology. Clark had invited me to apply.

I must have made a positive impression during the bathtub test in a hotel room in Hibbing that night!

As a postscript to this story, I made several more trips to the iron range of Minnesota for this and other projects. On one of them, on my way back, I returned to the Frank Lloyd Wright gas station in Cloquet. It was a beautiful fall day, and I continued from there on my route home through colorful boreal and deciduous forests, passing the pristine lakes and lush landscapes that fill Minnesota. I had always had a curiosity and urge to live elsewhere, but on this particular trip I realized that this was my home. My desire to leave it was extinguished!

What a great story! Love the problem solving and engineering history! Mindy

Thanks, nicely done. Will pass it on.

Steve