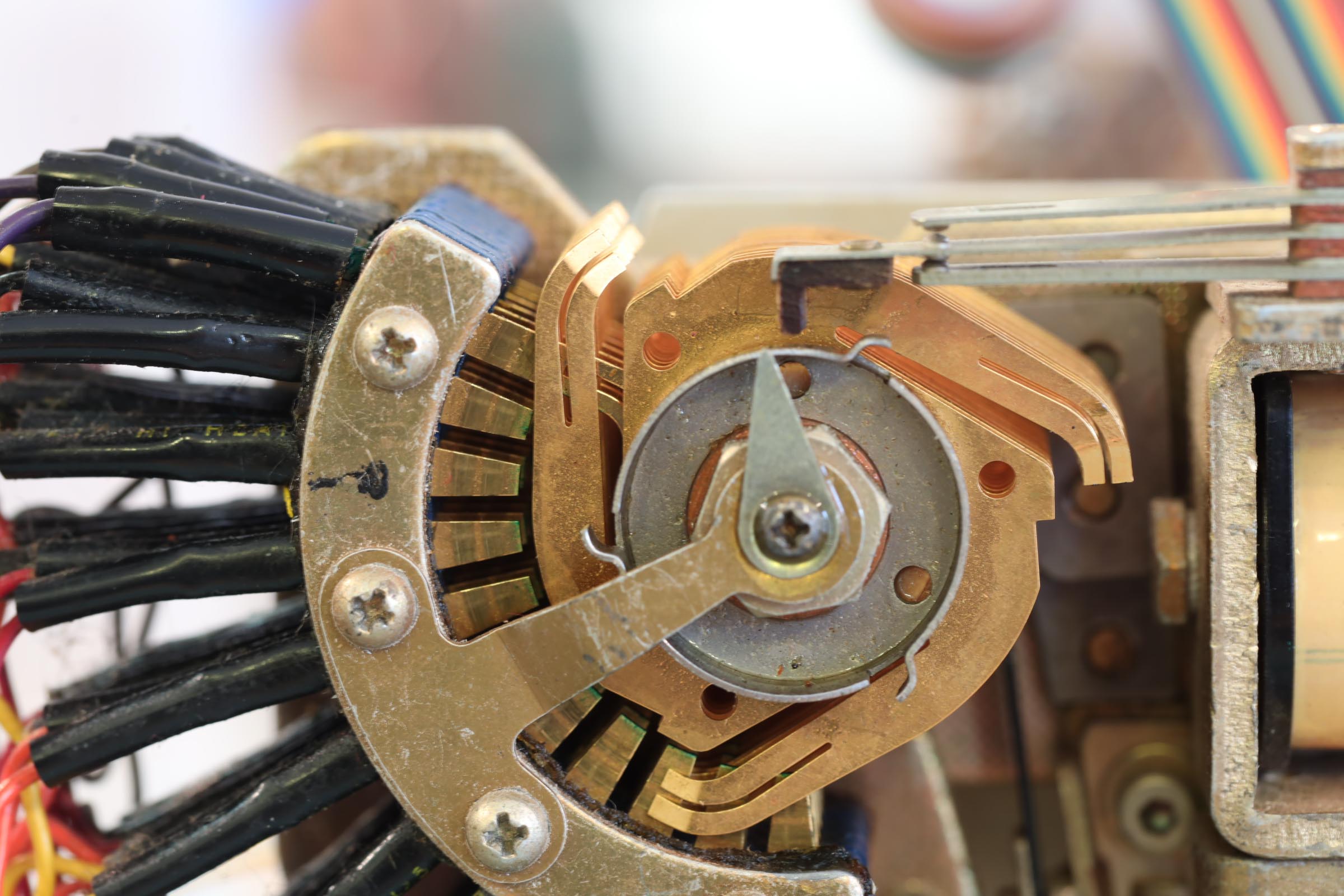

I re-wired the relay coils for the improved control circuit and hooked up the new power supplies. A set of micro-switches were used for setting the time—they momentarily applied power to the relays with each button push. I could now see if the relays still worked. They did!

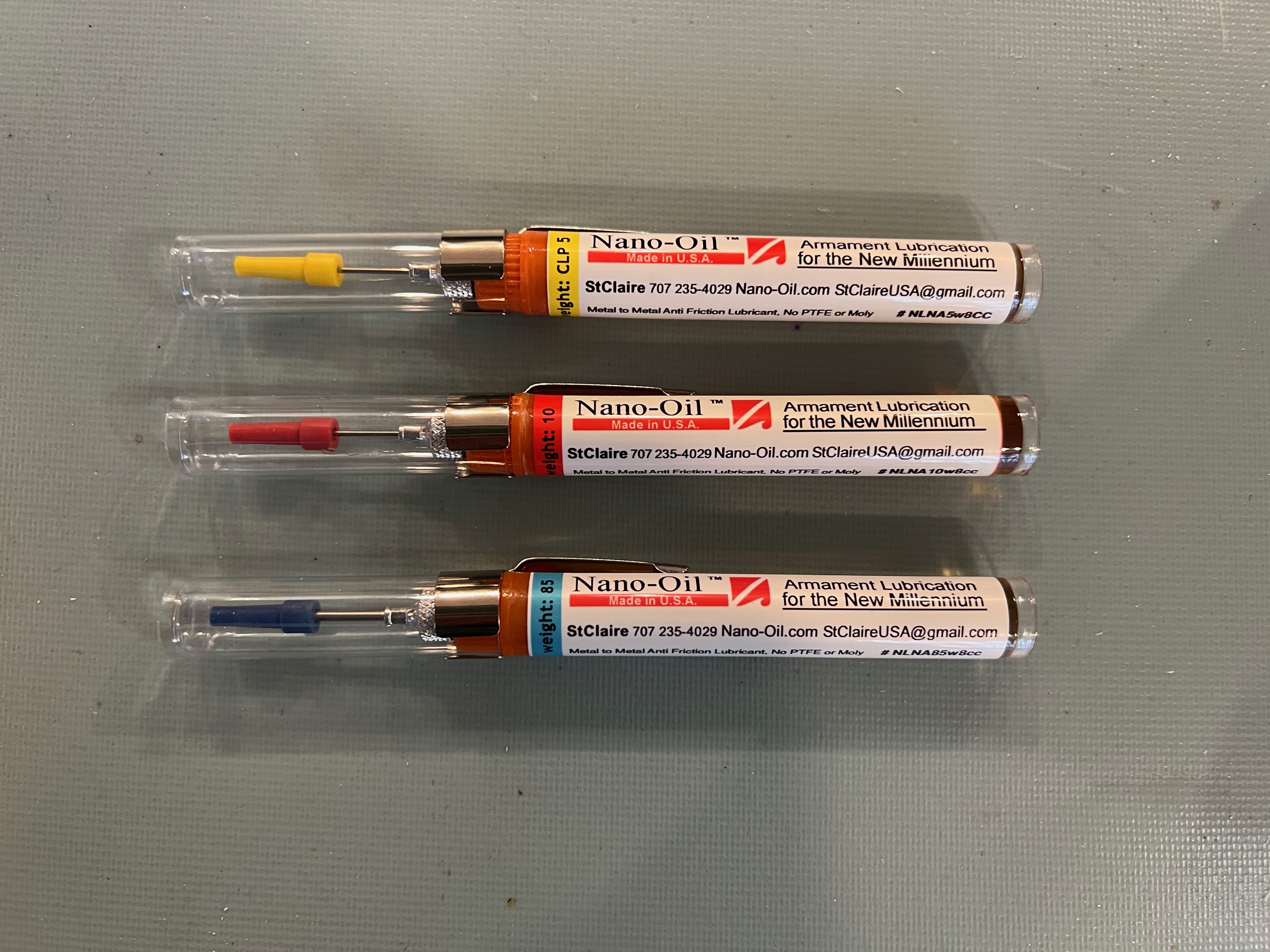

Well, they mostly worked. The contacts had tarnished and needed cleaning, and some of the mechanisms got stuck in one or more positions. I applied the usual treatment for things that stick—WD40, but it was not enough. The lubricant that finally allowed the decade stepper relays to move freely was something called “Nano-Oil”, a substance using “Magnetically induced Molecules of 0.09 microns”, that my son had gifted me a few years back. At the time I wondered what I would use it for, but he evidently saw my future need for it.

previous | The Relay Clock Restoration Project | next