Our next opportunity finally arrived two weeks later. Having been through two “dress rehearsals,” we knew what to expect.

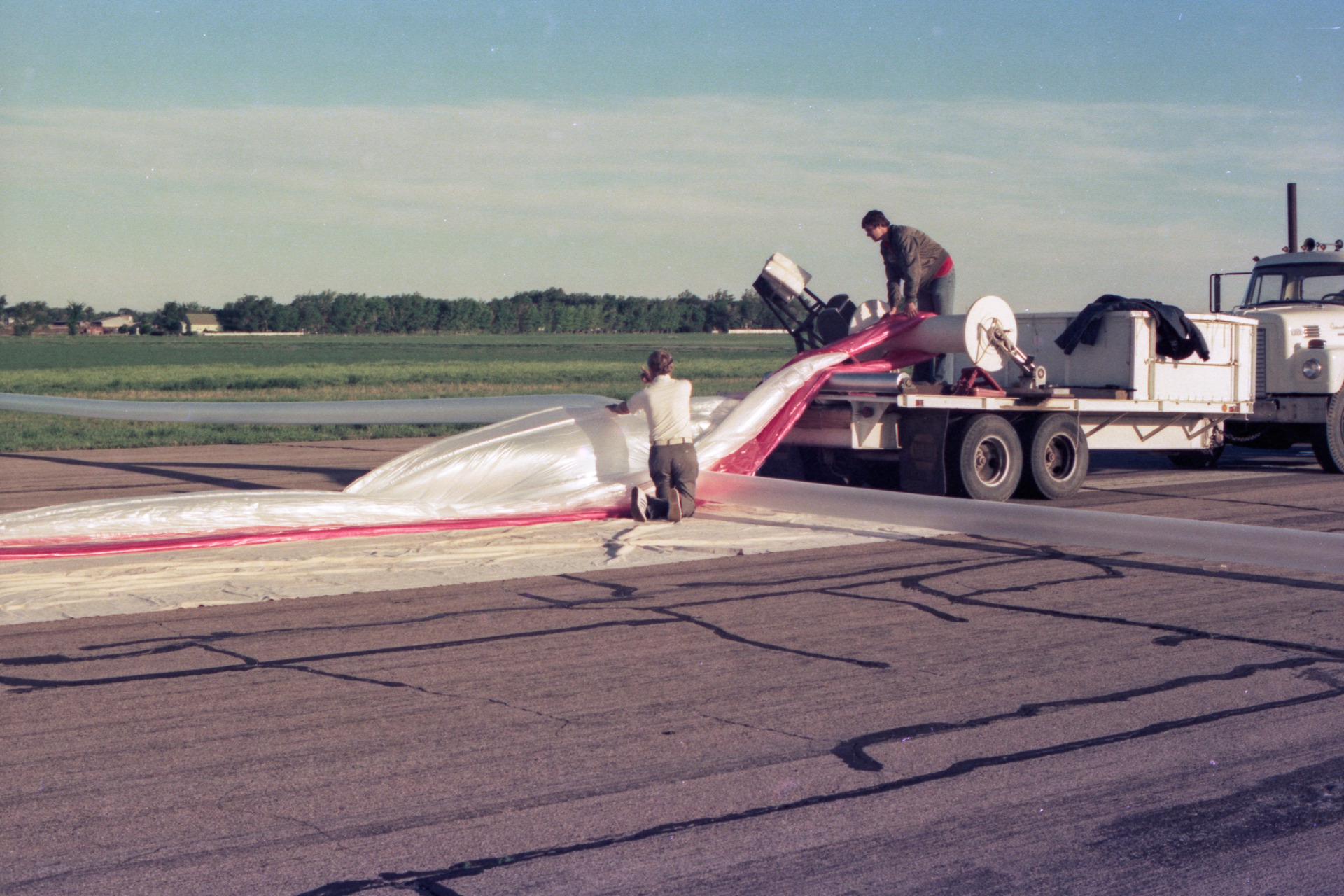

The procedure was to lay out the balloon on a protective tarp on the runway. The topmost section of the balloon, a small portion that would become the “bubble”, was fed through a retaining “spool” and folded back on itself. The top section had two tubes, made of balloon material, through which helium would be fed, inflating the bubble, which would gradually ease up from the tarp, eventually becoming large enough to lift itself off the ground entirely, with only the spool and the tension from the uninflated remainder keeping it in place.

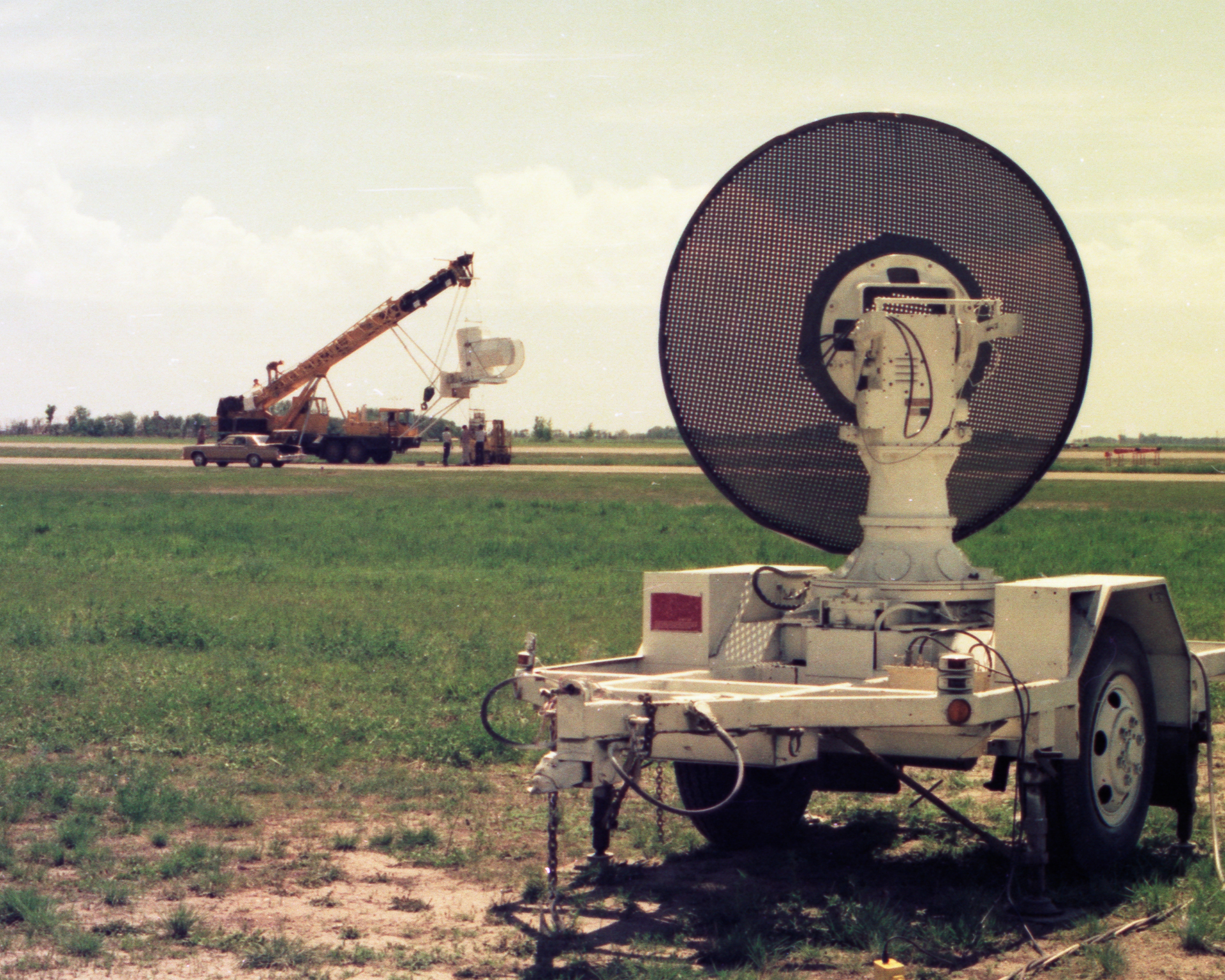

Meanwhile, at the other end, the panels of the balloon terminated at a common fitting, which was connected by cable to the payload, held at a safe height above the ground by a crane. At the Texas launch site in Palestine, a specialized vehicle, “Tiny Tim” is used for this function. It is highly maneuverable and has special arms that release the package at just the right moment in the launch sequence. Tiny Tim was too large to bring to South Dakota, so a local construction crane and operator was hired instead. Somehow the Texans had fitted it with a mechanism to perform the release.

The balloon is filled with helium, supplied by a semi-truck of cylinders containing the compressed gas. It takes quite a while to fill, creating a loud and penetrating hissing noise across the airfield. The crew near the filling tubes required hearing protection. When the required gas volume is met, the noise abruptly stops and the bubble of the balloon silently towers over and dwarfs the giant rig.

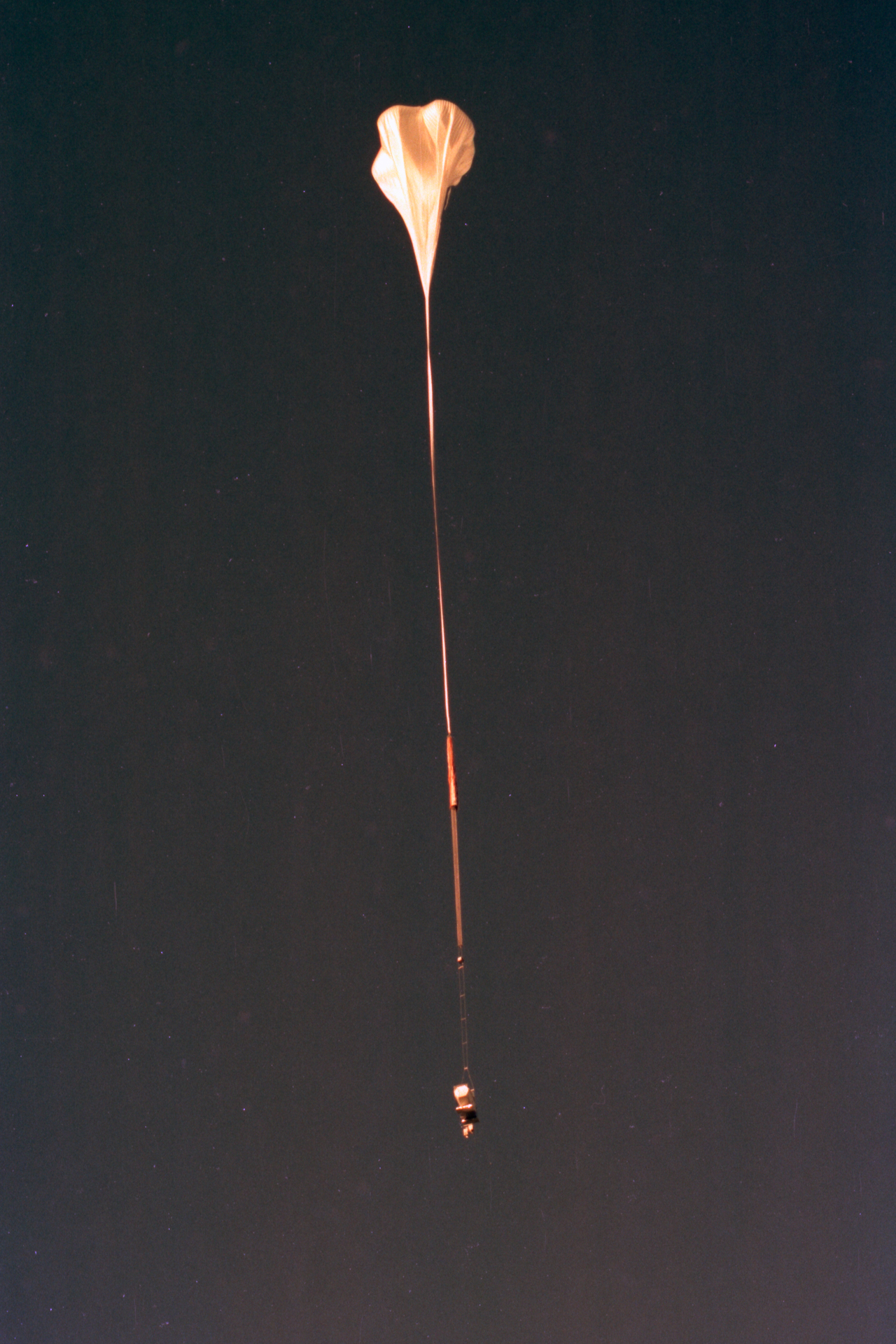

The spool holding the neck of the bubble has a mechanism that, when triggered, releases the balloon from its mooring. With nothing holding it down, the balloon floats up, lifting its long tail off the runway. The net forces cause the bubble to arc toward the payload, but not enough to lift it straight up. The crane must drive toward the motion, and when the cable is directly vertical and starting to provide the needed lift, the retaining mechanism is opened and the instrument is released. If the timing is right, the package will not drop back down to hit the ground, nor will it lurch up with a sudden jerk of upward buoyancy.

Keeping a nervous eye on the wind speed, we watched the Texas balloon crew perform this launch choreography. Finally, after the final equipment and telemetry checks were made, someone, I don’t know who, gave the order to launch.

The launch went well, averting the disaster stories we had heard from the Texans, and we breathed a sigh of relief as we watched the long assembly start on its journey to near space. When it got there, the bubble of helium would expand to fill the full volume of the balloon, and it would become as wide as it was tall.

The launch was exciting, but now the serious business of monitoring began. A data stream was radioed back that gave altitude and position information. When the balloon reached the target height of about 20 miles, data collection could begin in earnest. It was important to stay as high as possible for as long as possible. The balloon drifted with the high-altitude winds, which we had no control over, and rose up and down with temperature variations, over which we did have some control. The payload included ballast, containers of metal shot that had radio-controlled valves. When the temperature dropped, as it did during the darkness of night, the balloon would shrink, become less buoyant and drop in altitude. To compensate, we could lighten the load by releasing some ballast. As the first night progressed, numerous ballast drops were made to maintain height.

When the balloon saw the light of day and the temperatures recovered, it maintained its position more easily. But there was no way to compensate for movement with the wind. At these altitudes, the winds can exceed 100 miles per hour. We were about 1500 miles from the Pacific coast, which would yield a flight time of only 15 hours before we had to bring it back down and recover the instrument package. Fortunately, during the spring turnaround, the winds were lower. It would be another night and another day before the mission ended.

Great stuff!

Wow. Coordinating the cosmic ray detector with launch of the huge balloon was incredibly complicated. Congratulations.