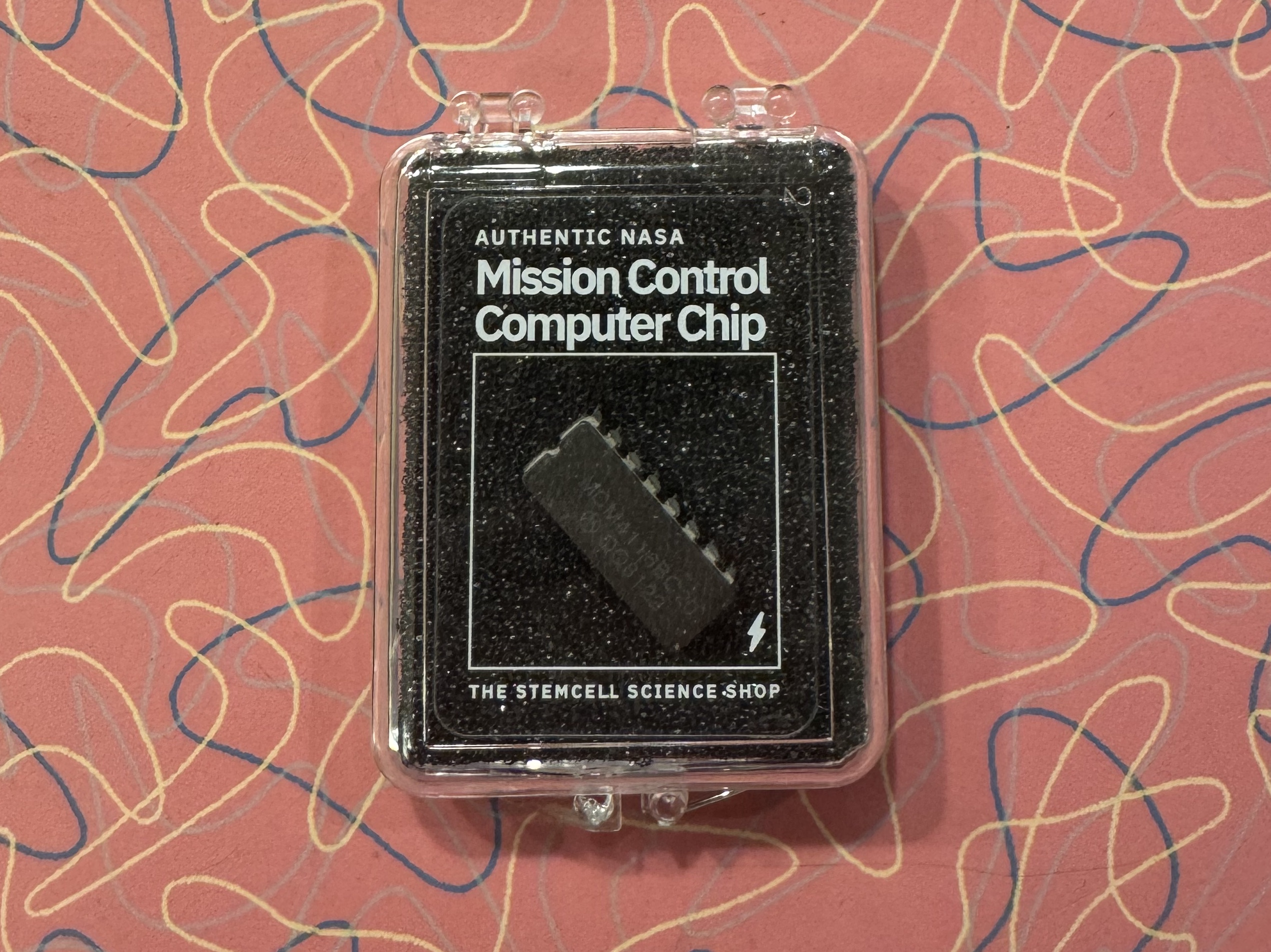

I was recently presented with a gift from a young family member. He thought I would get a kick out of a “NASA Mission Control Computer Chip.” And I did, even more than he could have imagined.

I suspect that an entrepreneur had acquired some decommissioned NASA equipment and found a way to monetize it by stripping the chips out of their sockets, packaging them, providing a backstory, and selling them to nostalgia seekers, space history nerds, and millennials looking for novel gifts for their boomer relatives. This is not a criticism. This is a fine way to keep these components from ending up in a scrap heap headed to a landfill and instead make a final tribute to a remarkable human project.

To someone born after the Apollo moon landing program, the artifacts of those times must seem just that: obsolete artifacts. There are still computer chips, of course, but they are smaller, more complex, and come in highly sophisticated packages that look nothing like those of that era. Just look inside a cell phone.

My pleasure at receiving this gift was not just the experience of once again seeing a 16-pin DIP (“dual inline package”). It was also the recalled memories of designing circuit boards with them in the 1970s. At that time, I worked for a small company that made geophysical instruments. We had employees, mostly women with fine motor skills, who hand-assembled these DIP packages, along with other electronic components onto circuit boards, soldering them into place and wiring the boards into the instrument chassis. I contributed to the design of those boards by figuring out how the digital chips needed to connect to each other.

I was curious what exact chip from mission control I had received. When I looked closely, I could see the part number stamped on its top: MCM 4116 BC20, along with the manufacturer’s logo and date code (8122- the 22nd week of 1981). This part number seemed familiar to me. I looked it up and found it to be a memory chip with 16,384 bits. Now even more memories flooded in! This was a milestone memory chip in its day!

And it was the very chip I had used in one of my first memory board designs. I was quite intimidated because it was in a class of memory called “dynamic,” which was a euphemism for memory that forgets rapidly. In order for it to not forget, it needed to be refreshed. And I had no idea how to do that.

There are now many different technologies used to store data, but in the 1970s, there were only a few, categorized by type. Read-only-memory, ROM, had data permanently etched in place. It was good for storing data that would never change, like program code and conversion tables. The other major memory type was, and is, random access memory, RAM. This is memory that can be written with any data pattern, and accessed later, in any order (randomly) to recover it. There were two types of RAM: static and dynamic. Static memory, SRAM (pronounced “ess-ram”), would retain its data state for as long as it was powered on. Dynamic memory, DRAM (“dee-ram”), as mentioned above, would fade away with time, measured in milliseconds.

Why would anyone bother with memory that didn’t remember much?

Capacity. It was possible to fit much more memory in a DRAM chip than an SRAM chip. This was due to the additional complexity (transistors) needed for the static memory cell to stay, well, static, and hold its value. In contrast, the DRAM cell comprised a single capacitor, a place to store electrons. As a result, DRAM chips had 4X the capacity of SRAM for the same size or cost.

Unfortunately, the electrons on the DRAM capacitors had the tendency to leak away. This can be compensated for by sensing the memory value before it fades, and then re-charging the capacitor to its original state. It is a lot of overhead to visit every memory cell, read it, and re-write it before time runs out, but memory was valuable, and the effort was deemed worth it.

I knew little of these underlying details of memory chips in 1977, but I did know that it was easy to design circuits using SRAM chips. Connect them up, and they seemed to “just work”. On the other hand, on hearing about the onerous demands and complexities of using DRAM, I was scared. It just seemed too complicated, and I didn’t think I knew enough to take it on. It might be really hard. So I resisted this project.

Eventually, I had to face the task. I obtained the data sheets and application notes for the DRAM chip I would be using: the 4116, just like the one recovered from mission control. In the days before the internet, this involved procuring the published data books from the parts vendor. I then dove into learning about dynamic memory and how to manage it.

I learned the basics that I described above, and I also learned that I didn’t have to read and re-write every cell. The chip could help out with that task. Memory was arranged in rows and columns of cells. If I could access each row, the chip would take care of refreshing all the columns in it! Other chips were available to invisibly help with accessing each row.

As I learned how to make the control circuits keep the memory refreshed, I realized that my fear had been unwarranted. This wasn’t so awful. It was not over my head. I knew how to do this!

I would eventually become skilled enough to use DRAM chips in high-end color displays, sometimes devoting many bytes of memory for every pixel, an unheard-of extravagance made possible with the increasing capacity and dropping costs of DRAM.

I took away a lesson from all this. Something may seem incredibly complex, like the ubiquitous example of “rocket science,” but a complex field is not necessarily a difficult field, especially to those who are in its midst and have learned along the way. As one learns a little, the next questions to ask become apparent and guide you to learn more.

As a result of this experience, I became less hesitant about taking on new and unfamiliar challenges. Confront the challenge and the results are better, and you are better.