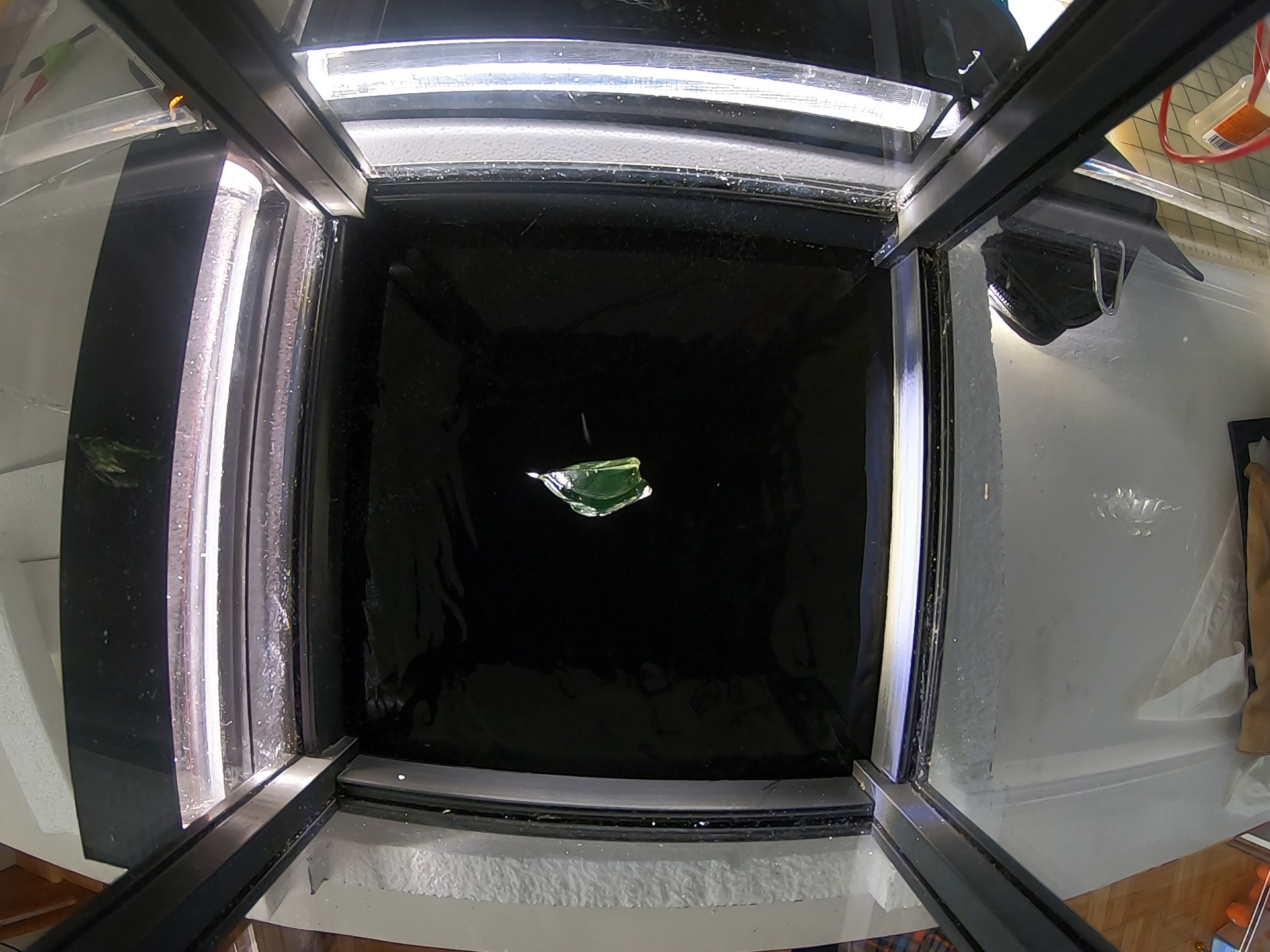

Years ago, after watching some YouTube videos on making cloud chambers, I tried my hand. A cloud chamber is one of the earliest techniques to see the paths of subatomic particles. It turns out that there is a natural background radiation of them and I wanted to see if I could watch these particles as they whizz around us. It seemed like a cool experiment.

The analogy I like to use is of a high altitude jet leaving a condensation trail behind it. You can see the contrail, but not the jet making it. In a cloud chamber, similar condensation physics is at work, but instead of engine exhaust, it is the particle’s ionization of gas molecules that triggers the condensation. The original Wilson cloud chambers used water vapor; modern chambers use alcohol, which is more easily managed.

My attempt to make one was less than satisfying. I recall staring at the mist at the bottom of the container and imagining that I was seeing patterns of droplets. Maybe I did, but it was not the thrilling experience of seeing the invisible that I was hoping for. I put the project aside. Until recently.

Continue reading